Latest Posts

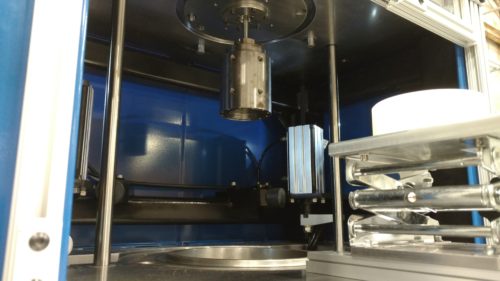

Success for the HQ-1 Spin Test System

Leave a CommentShops and factories need to regularly test rotors to ensure excellent performance and adherence to design or production requirements. The HQ-1 Spin Tester is a purpose-built bench that incorporates all basic spin testing. HQ-1 is designed for manufacturing environment, and most suitable for spin testing: High-speed electric motor armatures Small gas turbine disks and bladed […]

Protect Turbines & Engines with Subscale Turbine Particle Test Rigs

Leave a CommentSolid particulates—such as sand, volcanic ash or airborne pollutants produced through the burning of fossil fuels—pose a significant risk to power turbines and jet engines employed in the industrial, commercial, and military sectors. Whether natural or manmade, these contaminants can severely impact the performance and durability of these systems and, in some cases, cause damage […]

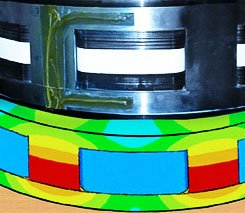

Optical Strain Measurement: What to Know

Leave a CommentOptical strain measurement is a non-contact measurement technique that employs digital image processing principles. Compared to traditional strain measurement methods, this technique provides a more streamlined solution for testing operations. The increase in testing efficiency is due largely to the elimination of the need for the modification of parts for lead-wire routing and sensor attachment. […]

Industrial Applications of Spin-Testing and Balancing

Leave a CommentPrecision testing of high-speed, high-performance motors and rotors is of paramount importance in today’s aerospace, automotive, and defense industries. Spin testing is performed to validate the design, durability, balance, and structural integrity of the motor. The material and structural behavior of the rotor, which ties to the efficiency of a machine, is of major import across the many varied applications […]

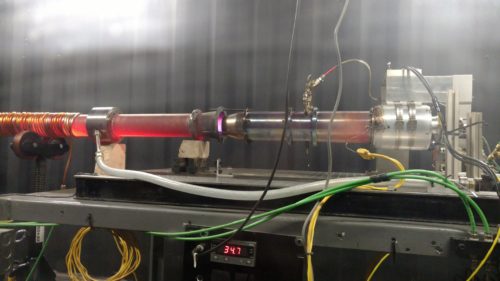

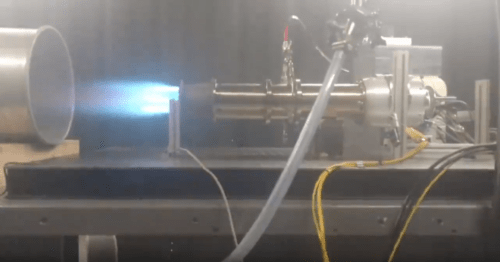

Test Devices Afterburner Small Jet Engine Test

Leave a CommentThe advancement of jet engine technology is directly tied to the pursuit of a hotter core, which continuously pushes the need for superior high-temperature materials, coatings and sensors. Testing nascent material and components in highly relevant conditions, and generating data, especially in the earliest phase of development work helps engineers and scientists to bridge the […]

Test Devices Improves Overall Production Capacity

Leave a CommentIn-House Machining Capabilities At Test Devices, Inc. we’ve made dramatic improvements in production capacity. We are not only producing more, but we’re also doing it faster than ever before. Along with dramatically shorter lead times, record production, and a plan for continued growth and improvement, here’s an outline of exciting developments at Test Devices. Test […]

Spin Testing Additively Manufactured or 3D-Printed Parts

Leave a CommentAdditive manufacturing (AM) is the process of building 3D workpieces layer by layer. Rather than traditional processes such as machining, which create forms by removing the material from stock material, additive manufacturing “prints” layers into a part from a computer model created with Computer Aided Design (CAD) software. The AM technique has been around for […]

Spin Testing for Manufacturing 101

Leave a CommentIn the quest to produce stronger, more durable, and cost effective rotating parts, manufacturers are turning to spin tests to help achieve these goals. Spin tests for manufacturers can be used to validate the stability and integrity of a part, or to enhance the desirable properties of the material. We will explore the differences between […]

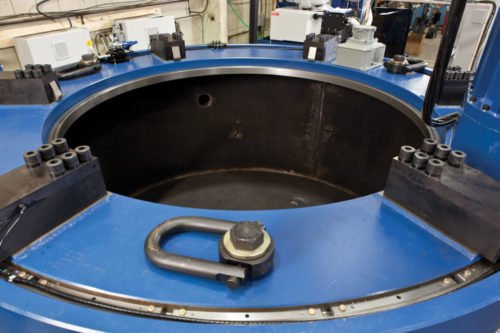

Expanding Capacity – Balancing Services

Leave a CommentRotating components such as jet engine disks and high-speed motor armatures must be balanced well to warrant a good performance and overall longevity of machines. Balancing machines pinpoint the exact amount and the location of unbalance in rotating components. Once these areas are identified, skilled technicians correct the unbalance level by either removing material in […]

The Competitive Advantages of Working with Test Devices

Leave a CommentTest Devices provides our clients with leading spin and subscale jet engine testing, balancing services, and test equipment. If your application involves high-speed, rotating components, Test Devices is your one-stop shop for testing and servicing needs. We provide spin tests for manufactured parts and design validation and offer a variety of add-on services such as […]