Latest Posts

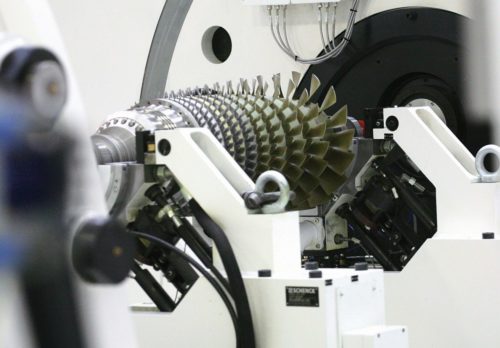

Benefits of Unbalance Budget Analysis for Rotors

Leave a CommentWhile rotor balancing can sometimes be treated as an afterthought within the aerospace industry, rotor unbalance has a significant impact on overall machine performance, durability, and quality. When designing any rotating part, engineers must pay careful attention to the unbalance correction strategy. To optimize rotor design for improved performance, Andreas Buschbeck et al. from SCHENCK […]

What Is Rotor Balancing and Why Is It Essential?

Leave a CommentRotors are a critical component used to convert electric or electromagnetic energy into rotational motion. For rotors to operate reliably, they must maintain even weight distribution across the rotational axis. Too much weight on one side creates uneven mass distribution known as “unbalance”. Rotating parts in any mechanical assembly can become unbalanced. Uneven weight distribution […]

Test Devices by SCHENCK Sponsors Award-Winning WPI Rocket Team

Leave a CommentAs part of our commitment to promote STEM, Test Devices by SCHENCK has been a proud sponsor of the Worcester Polytechnic Institute (WPI) High Power Rocketry Club. This student organization runs educational workshops on topics such as rocketry and robotics and also enters intercollegiate engineering competitions. Recently, the team has been winning impressive awards and […]

The Value of Fatigue Testing

Leave a CommentFatigue testing is a crucial procedure used by engineers and technicians to help predict the durability of a part or component under its operating conditions. To appreciate the value of fatigue testing, it is essential to first understand this testing service. Fatigue is a type of structural damage prevalent in cyclically loaded structures. The fatigue […]

How To Avoid Major Causes of Unbalanced Parts

Leave a CommentUnbalanced components can lead to electrical motor failures that necessitate costly investigation, repairs, or replacement. The easiest way to avoid this is to properly balance the rotor during the manufacturing stage. Unbalance happens when a rotating component’s center of mass, or inertia axis, becomes unaligned with its center of rotation, or geometric axis. It causes […]

Testing for eMotors: A Case Study

Leave a CommentHigh-speed rotating components in eMotors require accurate spin testing to ensure safety, reliability, and performance. At Test Devices by SCHENCK, we offer the most advanced balancing and spin testing services on the market. View the case studies below for a better look into how we serve clients in the electric mobility industry with our expert […]

Spin Testing Improves ePropulsion Rotor Design

Leave a CommentDeveloping sustainable transportation solutions is an increasingly high-priority goal in the aviation industry. Amongst the emerging contenders of electrified aircraft, exciting trends include the development of delivery drones and air taxis (eVTOLs). These new vehicles are designed to fly at low altitudes over heavily populated areas, requiring focused attention on its electric propulsion systems for […]

New ISO Certifications

Leave a CommentAt Test Devices by SCHENCK, we have an unparalleled and proven reputation for innovation and safety. We deliver the world’s most accurate and advanced spin testing services and equipment to clients in various industries, including aerospace, automotive, energy, defense, electric motors, medical, and commercial space. To illustrate our commitment to safety and the environment, we’re […]

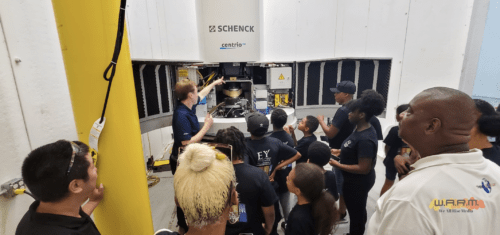

Doing Our Part: Test Devices’ Community Outreach

Leave a CommentTest Devices is a business unit of Schenck USA Corp.; we perform engineering tests, and we also have outsourced production services at our other Hudson location. In early August, we welcomed a group of students from Brockton High School. As a part of their summer program, the students visited Test Devices to learn what we […]

Green Technology: The Mobility of Tomorrow

Leave a CommentWhile the COVID pandemic has posed significant challenges worldwide, it also created an opportunity for us to slow down and reflect on vulnerabilities and inefficiencies in many areas of our social and economic structures. One of the concerns is our efforts towards sustainability, especially in regard to transportation. Dramatic reduction in transportation traffic during the […]