Spin Testing Services

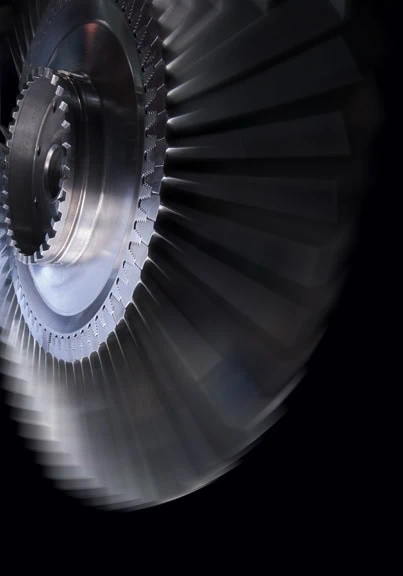

Machine parts that rotate at high speeds, like jet engine disks, are crucial components of modern high-performance machines. These high-speed rotors store a substantial amount of rotational kinetic energy. In the event of a part failure, this stored energy is quickly released, leading to catastrophic damage. Spin testing services help our customers to enhance the performance of their product design and prevent such accidents from happening.

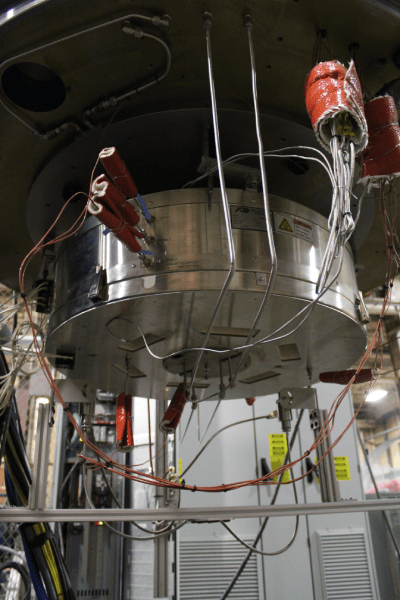

Spin testing, introduced over fifty years ago, is a method used to validate the structural integrity and durability of high-speed rotating parts. Today, modern spin testing is a complex engineering project that involves various testing environments, instrumentation, and control systems, all carefully planned out. The data gathered from these tests helps our customers understand how their critical rotating parts behave and the reasons behind any failures. This knowledge enables more effective design improvements to be made.

Test Devices by SCHENCK offers expert spin test services. We serve a wide array of OEMs and other clients who work with advanced, high-speed rotating parts. Our team develops innovative solutions to challenging problems in engineering testing and manufacturing spin processes. Our spin testing services support design validation, manufacturing processes, and critical engine part certification.

Below, you can learn more about the spin tests we offer for R&D and product development purposes.

Spin Testing for R&D and Product Development

Spin testing has traditionally been a critical step in product validation, particularly in industries like aerospace, where it is a requirement for the airworthiness certification. However, there is a growing recognition among customers of the benefits of conducting spin tests earlier in the product development process.

Advancements in numerical modeling techniques have made it possible to extract valuable insights from representative or subscale spin tests. By analyzing the data obtained from these tests, engineers can fine-tune materials and numerical models to optimize rotor designs and improve the chances of first article success. Integrating spin testing into the early stages of product development allows for the early identification of potential issues and the implementation of necessary adjustments. This proactive approach can help prevent costly redesigns and delays further down the line, ultimately saving time and resources.

Spin testing improves rotor design and ensures optimum performance of finished products without unexpected failure. Test Devices by SCHENCK offers several types of spin testing for design validation applications:

- Overspeed Tests. A rotating component is accelerated to speeds greater than those seen during operation. We perform overspeed testing both as an engineering investigation and for product certification purposes.

- Low Cycle Fatigue (LCF) Tests. LCF tests are used to determine the fatigue life of rotating components, a critical step in establishing their safe operational lifespan. Our services feature advanced rapid cycling capabilities that expedite testing programs.

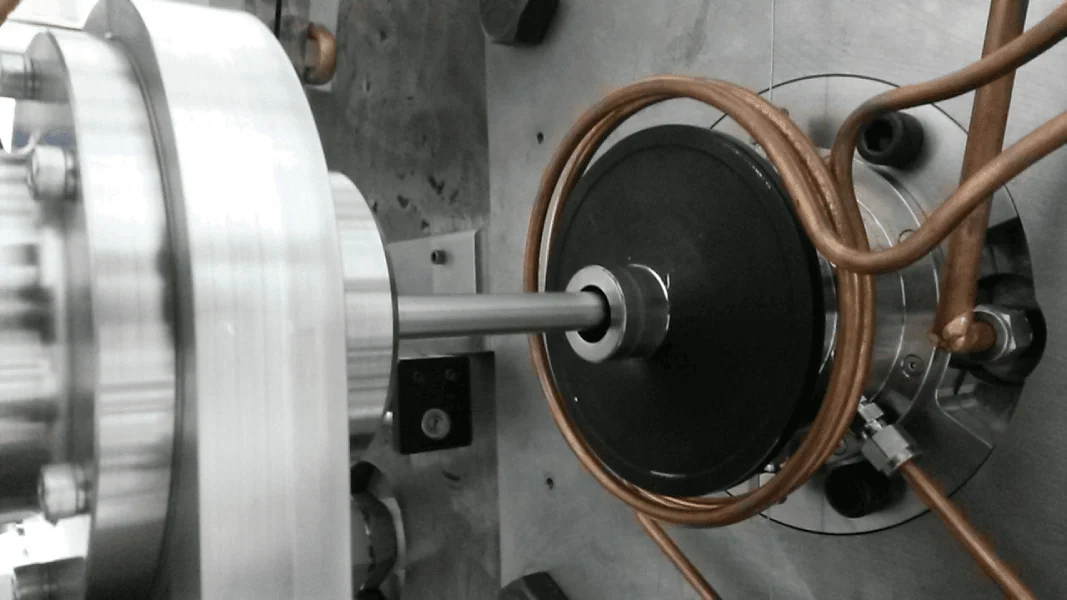

- Dynamic Spin Tests – Including High Cycle Fatigue (HCF). Dynamic spin testing is a valuable tool for studying the vibratory behavior of bladed rotors and assessing the effectiveness of damper designs. Furthermore, it can be utilized to evaluate the high cycle fatigue life of blades and bladed rotors.

- Test Environments. We can conduct different types of spin tests in various test environments, ranging from room temperature to uniformly heated high temperature conditions, thermal gradients, and cryogenic conditions.

Industries We Serve

Test Devices by SCHENCK is a trusted testing partner for clients throughout the following industries:

- Aerospace

- Automotive

- Electric Motors (eMobility, eDrive, ePropulsion)

- Energy

- Commercial Space

- Defense

Contact Test Devices by SCHENCK for Spin Testing Services

Test Devices by SCHENK understands the vital nature of engineering testing to ensure the performance of rotating components. For over 50 years, we’ve been a leader in spin testing services, with an unparalleled reputation for safety and innovation. We use the world’s most advanced spin testing equipment to develop highly realistic test scenarios.

While spin testing projects can often be complicated, our expert test engineers make the process as convenient as possible. We will guide you through the entire process, from design to execution, and offer hands-on support in analyzing your test data results. With our state-of-the-art facility, featuring an in-house machine shop and CMM inspection machines, you’ll obtain high-quality results quickly.

Test Devices by SCHENCK is ITAR-registered, with engineering processes that conform to AS9001 Aerospace standard. We are also ISO 9001:2015 certified, ensuring all of our testing services adhere to the highest possible quality standards. For more information on our spin testing capabilities, contact us or request a quote today.