Consulting Services

Noise and vibration are key concerns in defining vehicle characteristics that affect the quality of the ride and passenger experience. In some cases, even at lower intensity levels, noise and vibration can be a cause of operational and health hazards. Beyond being a nuisance, structural vibration is a well-known cause of issues and damage in electronics and structural joints, and contributes to fatigue damage.

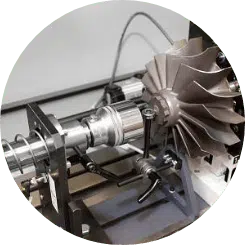

Rotating parts, such as motors, turbines, propulsors, power generators, and other transmission parts are ubiquitous and are common sources of undesirable noise and vibrations. Schenck specializes in helping you minimize the risk of undesirable vibration and noise from the source. Test Devices by Schenck offers engineering consultation services to guide you through design development, planning production processes for balancing your high-speed rotating parts, or troubleshooting existing issues.

As a Schenck company, Test Devices has access to the world’s premier balancing and testing equipment for rotational components. Leveraging our expertise in designing, balancing, and testing high-speed rotating parts, we can help you determine the most efficient approach to address your rotor balancing and testing needs, especially in a production environment. Some of the key focus areas of our consulting services are outlined below.

Analysis of Your Rotor

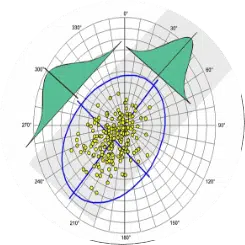

We perform numerical model-based analysis to understand the effect of manufacturing variables, such as dimensional tolerances, to assess the resulting magnitude of unbalance in the rotor.

The analysis produces a probabilistic model of unbalance distribution that may result from a specified manufacturing process and the type of rotor. Based on the analysis results, we can evaluate the feasibility of correcting the predicted amount of unbalance, as well as make a recommendation on the optimal way to design the rotor to meet your balancing requirements.

Analysis of Your Rotor" title="Analysis of Your Rotor">

Analysis of Your Rotor" title="Analysis of Your Rotor"> Hiring us to perform this analysis early in the design and development stage of your rotating parts will save you from the headaches associated with balancing issues – especially in the production stage.

Learn more about how unbalance budgeting optimizes rotor design for assembly performance.

Balance Tooling Design

Designing tooling for rotor balancing may appear to be a trivial task, but this is another underappreciated area of expertise that could result in a persistent in-production problem if you are ill-prepared.

Designing good balance tooling is not limited to making a piece of precision machined shafting. The designer must understand the interaction of the tooling with the balancing machine, the detail of the interface between the tooling and the rotor, the calibration process, and its repeatability (the effect of potential error in the assembly).

If you require a real engineering solution for your rotor balancing, we are here to serve your needs.

Troubleshooting & Process Optimization

It is not uncommon to hear that some of our customers have been suffering unnecessarily due to long-running balancing issues. Oftentimes, rotor balancing work can devolve into an “established process” where no one knows the engineering logic behind the procedures.

“The devil is in details”, especially when it comes to precision work like rotor balancing. Having our experts look at your balancing process could uncover and alleviate recurring issues and reduce production costs. Through analysis and expertise, our specialists could help you identify the root cause of your problems, and recommend a suitable solution for both your short-term and longer-term goals.

WE STRIVE TO HELP YOU ACHIEVE:

- Optimization of the balancing process

- Integration into the client’s production operation

- Production of high-quality products at a reduced cost

Testing and Validating the Result

As the industry leader in high-speed rotor testing, Test Devices by Schenck can help you validate rotor behavior in an economical and expeditious manner. Beyond checking the effect of rotor unbalance at the operating speed, spin testing allows our customers to study and understand the structural instability that may result from the centrifugal load and failure mechanism of the rotor.

We can perform various types of spin tests in our state-of-the-art test facility, such as:

All these tests can be performed in varying test environments (heated/cryogenic conditions). We offer the most cutting-edge, relevant set of data and measurement techniques to help you observe and evaluate the rotor of interest. The test data like this is a key ingredient for improving and refining the design and the performance of the high-speed rotors designed for high-performance machines.

ADDITIONAL SPIN TESTING RESOURCES:

Add-On Services

In addition to expert engineering consulting, Test Devices also offers some unique data measurement and analysis techniques:

Tooling & Arbor Engineering

When spin testing a rotating component, the tooling used to hold it is exposed to the same speed-induced stress as the device under test (DUT). Simply by holding the DUT, tooling can affect the internal stresses of the part. As such, a common challenge of designing spin test tooling is to safely control the DUT without affecting the final test results.

At Test Devices by Schenck, we create spin test tooling that closely mimics the way in which the DUT is held and the stresses it is exposed to under realistic operating conditions. Doing so guarantees that the test results are in line with real-world conditions.

Our experts are available to consult you on designing and planning of spin tests, project management, executing the test, and deduction and analysis of the data.

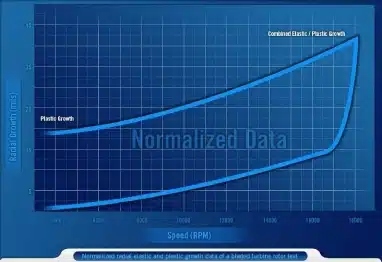

Growth Measurement and Profile Measurement at Speed

We have developed methods to measure plastic and elastic radial growth of rotational components in real-time during a spin test. Doing so helps to get a better understanding of the component when exposed to realistic temperatures and centrifugal loading. We can measure this radial growth as the speed is increased right up to the point of failure (bursting), and we can also take measurements at temperature. In-situ growth measurement is particularly useful in understanding the point, or speed, at which plasticity occurs.

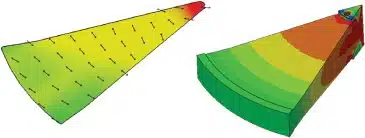

The expansion measurement is an enhanced version of the growth measurement system that maps the profile of the rotor (outer or inner diameters) at speed. Visualizing the shape of the rotor under CF load helps our customers to “see” the detail of part deformation and pertinent localized behavior in detail.

Rotor Optical Strain Survey

Rotor optical strain measurement is a type of strain measurement technique that uses digital image processing. This non-contact measurement method eliminates the need for modifying parts for sensor attachment and lead-wire routing, which is required for traditional strain gauge instrumentation.

Test Devices by Schenck developed the Rotor Optical Strain System (ROSS), which involves designating a target area on the test rotor’s surface. The target area is then marked with an engineering pattern. We can calculate strain data from the captured images via a digital image correlation (DIC) process.

Strain Survey

Strain surveys play a key role in helping engineers understand how to improve their designs to enhance performance and lifespan while lowering material costs. When strain issues go undetected, they can lead to costly consequences when it comes to system performance, business reputation, and personal safety.

At Test Devices by Schenck, we offer comprehensive strain surveys of rotating parts. Using the information gathered from these tests, engineers can examine complex components, understand assembly stresses, and discover material behavior when exposed to operational loads under realistic conditions.

High-Speed Video Imaging

The purpose of conventional spin pit burst testing is to discover the speed at which the rotating component fails because of centrifugal stress. Understanding this failure speed helps customers determine the safety margin during normal operation.

Compared to traditional burst tests that only provide the failure speed, our High-Speed Burst Testing Video capabilities allow us to provide visual documentation to aid in determining the cause of the burst. This allows designers to evaluate significant information, such as where the fracture begins, how it spreads, and the size of the resulting burst fragments.

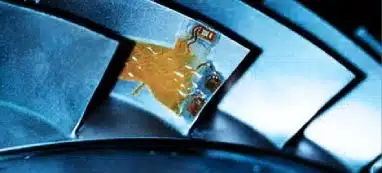

Real-Time Crack Detection System

Low Cycle Fatigue (LCF) testing is a critical tool for life assessment. During this testing process, rotating parts, including those for electric motors, are repeatedly cycled from low speed (low stress) to operational speed (high stress) for a specific number of cycles at ambient and high temperature gradients.

LCF testing allows for real-time monitoring of components. This not only provides critical information such as when the crack initiates but also reduces testing downtime needed for component inspection. When left undetected, cracks in rotating parts can lead to component failure, resulting in potential personal injury and asset damage. Our patented Real Time Rotor Health Monitoring System is capable of detecting crack initiation as well as monitoring tooling and component flaws during LCF testing with 80-90% accuracy.

Partner With Test Devices For Consulting Services

Test Devices by Schenck can guide you from the earliest stages of product development and offer support post-production to ensure continuous satisfaction. With expertise in product development from prototyping, testing, optimization, to quality assurance, we ensure that your product will operate at optimal performance throughout its life cycle. Equipped with comprehensive testing facilities to aid the analysis and prediction of a component’s real-world performance, we achieve sustainable balancing solutions for each of our clients.

Our clients have come to expect excellent products that deliver low noise emissions, long service life, and high productivity. Test Devices by Schenck relies on a quality management system in compliance with ISO 9001 and AS9100 standards to ensure our services meet or exceed industry standards. We have over 50 years of experience in delivering excellent services in the United States from our 50,000-square-foot testing facility in Hudson, MA, backed by Schenck’s superior rotational testing systems.Contact us to learn more about our consulting services.

Recommended Resources

Click below to download one of our most popular resources!