What are the Benefits of Merging With SCHENCK?

Test Devices by SCHENCK has built a strong reputation in the spin testing business. Since SCHENCK acquired Test Devices in 2017, we have been able to expand our services and improve our capabilities. We provide end-to-end services in spin testing, from one-off engineering testing to high-volume spin test processes for production. By combining our knowledge with SCHENCK’s global network, we can deliver broad expertise in both high speed spin testing and precision rotor balancing.

The financial backing and the support of SCHENCK grant us a competitive edge and give our clients access to services at a larger scale. Whether you require engineering consulting, test project management, balancing, or spin test services, we have the unique expertise to meet your needs.

The benefits of merging with SCHENCK include:

The Opening of a New Research Facility and Expanding Capabilities

Our Hudson site, Test Devices by SCHENCK, is now The North American Center of Excellence for testing. SCHENCK has heavily invested in this facility to upgrade its equipment, increase its capacity, and prepare for growing demands in spin testing resulting from the electrification in aircraft, vehicles, and other industries.

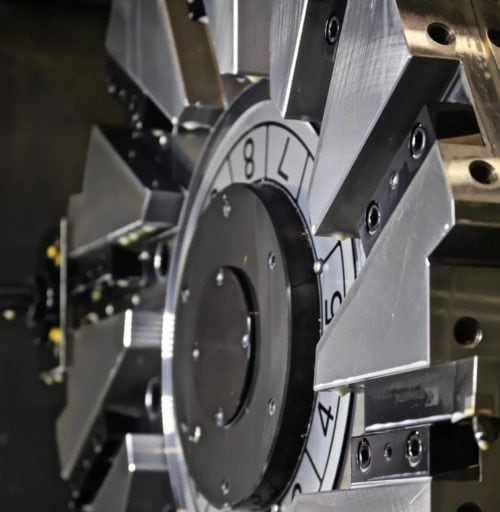

One of the recent and significant investments SCHENCK has made is the addition of the new Centrio spin testing system at our Hudson facility. The system is the same one used by our Germany-based parent company SCHENCK ROTEC. Sharing the same system enhances the collaboration between the groups, the sharing of knowledge base and forms an excellent foundation to grow our testing capabilities for the betterment of our clients and their products.

What Is the Centrio Spin Testing System?

It is the “cutting-edge” spin testers in the world, giving us the capability to perform various advanced tests and data measurements to evaluate the customers’ rotors, especially for emerging e-mobility applications.

Being Able to Target New and Emerging Markets

Precision balancing and spin testing services also are essential elements in the production of EVs and other electric propulsion or mobility products. With the financial and technological backing from SCHENCK, a recognized global brand, Test Devices by SCHENCK is now positioned well to serve the growing needs of our customers beyond engineering testing. We offer some of the innovative and dependable solutions for customers with:

- Mass production automotive parts

- Large-scale production aerospace components

- eVTOLs such as drones and air taxis

SCHENCK has a deep customer base in both the automotive and aerospace sectors. We offer innovative testing and production support services with the highest standard of process integrity and quality. SCHENCK is very familiar with and equipped to meet the rigorous pace of mass-production work required in the automotive industry.

SCHENCK has a deep customer base in both the automotive and aerospace sectors. We offer innovative testing and production support services with the highest standard of process integrity and quality. SCHENCK is very familiar with and equipped to meet the rigorous pace of mass-production work required in the automotive industry.

A One-Stop-Shop Facility

Test Devices by SCHENCK is dedicated to delivering top-quality products and services that meet or exceed customer requirements. We achieve this through continuous process and product innovation, ongoing improvements of our quality management system, and compliance with ISO9001 and AS9100 standards.

As your one-stop shop for engineering testing and outsourced production hub, we offer balancing, spin testing, and semi-finished machining services. We are equipped to handle all your needs from one-off pilot projects to managing your outsourced manufacturing operations.

See How Test Devices Can Help Your Organization Today

Turn to Test Devices by SCHENCK today for expert testing processes and more. Through support from our parent company SCHENCK USA, we offer a comprehensive range of spin testing services for the automotive, aviation, and transportation industries. Contact us today to learn more.

Fatigue test data enables electric motor manufacturers to understand the durability limit of the motor rotors, develop a dependable product life model to define appropriate product servicing life as well as establish a maintenance service schedule – the goal is to prevent any unexpected failure in the service life of the machine. Additionally, the data allows engineers to proactively plan for design improvements and modifications.

Fatigue test data enables electric motor manufacturers to understand the durability limit of the motor rotors, develop a dependable product life model to define appropriate product servicing life as well as establish a maintenance service schedule – the goal is to prevent any unexpected failure in the service life of the machine. Additionally, the data allows engineers to proactively plan for design improvements and modifications.

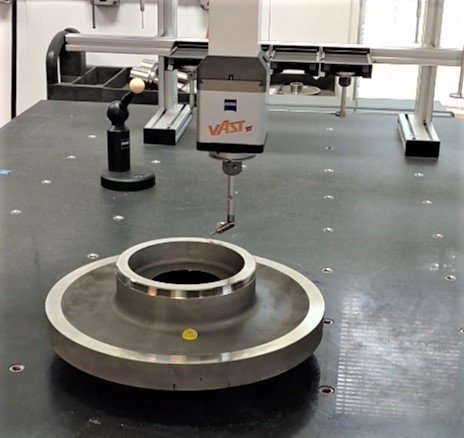

At Test Devices by SCHENCK, our skilled and experienced staff brings extensive expertise to the manufacture of safety-critical rotating components made from challenging aerospace alloys. With a great deal of experience creating or adhering to the frozen manufacturing processes used by original equipment manufacturers (OEMs) in the aerospace sector, allowing us to guarantee a high rate of repeatability across each production run.

At Test Devices by SCHENCK, our skilled and experienced staff brings extensive expertise to the manufacture of safety-critical rotating components made from challenging aerospace alloys. With a great deal of experience creating or adhering to the frozen manufacturing processes used by original equipment manufacturers (OEMs) in the aerospace sector, allowing us to guarantee a high rate of repeatability across each production run.

We are committed to providing

We are committed to providing