Test Devices by SCHENCK Sponsors Award-Winning WPI Rocket Team

As part of our commitment to promote STEM, Test Devices by SCHENCK has been a proud sponsor of the Worcester Polytechnic Institute (WPI) High Power Rocketry Club. This student organization runs educational workshops on topics such as rocketry and robotics and also enters intercollegiate engineering competitions. Recently, the team has been winning impressive awards and gaining visible results.

What is the WPI HPRC?

The WPI HPRC is Worcester Polytechnic Institute’s High Power Rocketry Club, a student organization dedicated to rocket engineering and STEM education. A large portion of the club’s time is devoted to pursuing hands-on learning as they design, build, test and launch sounding rockets. The HPRC also believes that taking part in high-level competitions is an important aspect of cultivating technical expertise in the next generation of engineers.

Participating in rocketry competitions allows this group to develop a more in-depth knowledge of the engineering design process. HPRC members come from diverse backgrounds and disciplines and are able to channel their unique experiences into engaging collaborative projects. Over the years, club interest has grown and today the HPRC includes a member base of over 200 students. Every member actively participates in managerial or technical tasks, fostering an inclusive and engaged educational environment. An important aspect of the HPRC is to cultivate leadership skills as they work as a team in a professional and intense goal-oriented atmosphere for students to navigate.

WPI’s Competition Journey

WPI’s High Power Rocketry Club originated in 2018 with the founding of the WPI University Student Launch Initiative (USLI). That year, WPI’s team competed in NASA’s annual USLI competition. Enthusiastic student response led to the first competition rocketry launch the following year with Project G.O.A.T.S. The goal for this launch was a target apogee of 4,094 ft.; however, failure occurred at 800 ft.

After a year of delays due to the COVID-19 pandemic, WPI re-entered the competition scene in 2021 with a new and improved rocket for Project Sirius and Polaris. This project’s test bed launch was instrumental in preparing for the team’s most demanding competition yet, the 2022 Spaceport America Cup’s Intercollegiate Rocket Engineering Competition. Hosted by the Experimental Sounding Rocket Association, 158 teams from 24 countries participated in the world’s largest intercollegiate rocket engineering competition.

At this event, nearly 2,000 students from around the globe gathered to share their passion for high-power rocketry. In 2022, WPI’s rocket team experienced launch failure at this event, they used lessons learned from the setback to improve their rocket design and came back with more skill than ever before in 2023.

Today, with only five years of operational experience, WPI has obtained advanced technical aptitude and emerged as a leading competitor in the world’s most challenging rocketry competitions, like the SAC IREC. In 2024, the team plans to compete in the 10K Solid Commercial Off-the-Shelf Division at the SAC IREC. Their mission is to launch the team’s high-power rocket and payload system to an apogee of 10,000 ft. with another successful recovery.

Competition Success and Awards

Throughout HPRC’s history, they have experienced many impressive achievements and awards. Each year as they participate in challenging international competitions, they demonstrate an impressive dedication to engineering excellence. The team has attended the Spaceport America Cup’s Intercollegiate Rocket Engineering Competition (SAC IREC) annually since 2021, collecting new awards each year. Their past competition successes include:

- SAC IREC 2022 Team Sportsmanship Award

- SAC IREC 2023 3rd Place Payload Challenge Award, Space Dynamics Laboratory

- SAC IREC 2023 Jim Furfaro Award for Technical Excellence

Most recently, in 2023, the club obtained 2.64% within their 10,000 ft. target apogee. This feat allowed them to beat out over 100 internationally competing teams to win two awards for technical achievement. As a platinum-level sponsor, Test Devices by SCHENCK is proud to support the WPI HPRC and its efforts to foster engineering excellence in our local community.

Learn More About Test Devices by SCHENCK: Leading the Way in Rotational Parts

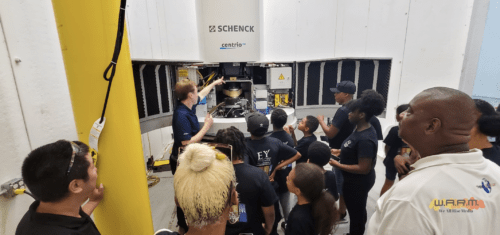

At Test Devices by SCHENCK, we’re passionate about innovative technology and work continuously to advance the science of rotational testing. Taking part in community outreach programs is an important part of this mission. In addition to supporting WPI’s rocketry team, we also host local students for aerospace industry events. Here, we share knowledge about our work, promote STEM education, and inspire the next generation of scientists and engineers. Explore our website to learn more about what we do and contact us with any questions. If you have a project you’d like to work with us on, request a quote today.

To combat the global warming, electrifying the cars and airplanes are not enough. We must think of a way to make the whole energy supply chain green. Starting from how we generate fuel (or energy), transport and distribute it, and eventually how the byproduct of the fuel impacts the environment – the new greener supply chain must be a sustainable close-looped cycle.

To combat the global warming, electrifying the cars and airplanes are not enough. We must think of a way to make the whole energy supply chain green. Starting from how we generate fuel (or energy), transport and distribute it, and eventually how the byproduct of the fuel impacts the environment – the new greener supply chain must be a sustainable close-looped cycle.