Expanding Capacity – Balancing Services

Rotating components such as jet engine disks and high-speed motor armatures must be balanced well to warrant a good performance and overall longevity of machines. Balancing machines pinpoint the exact amount and the location of unbalance in rotating components. Once these areas are identified, skilled technicians correct the unbalance level by either removing material in heavy areas through drilling, milling, or other processes or by adding mass (weld or bolt additional material onto areas that are too light).

Unbalance resulting from eccentricities between the center of the rotor’s gravity and the axis of rotation causes the heavier side of the rotor to exert more centrifugal load. The unbalance in the rotor often directly impact the levels of noise, vibration, wear, and leads to significant reduction in service life of the equipment. In some applications, unbalanced rotors are even considered to be a safety hazard if machine failure can result in personal injury or property damage.

New Updates for TDI’s Balancing Machines

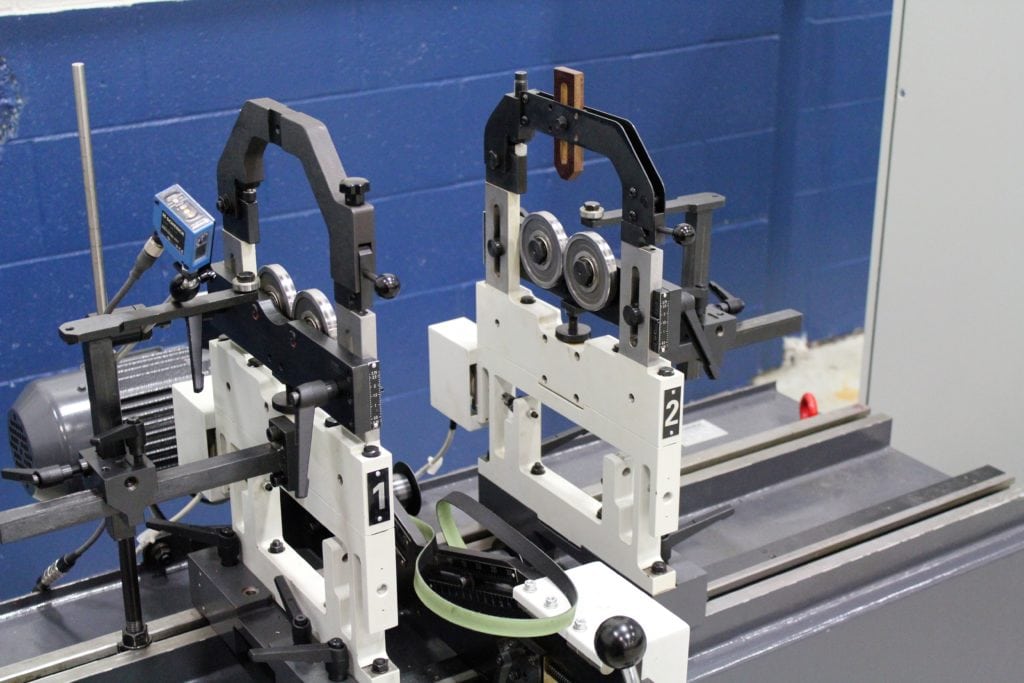

For the past four decades, Test Devices Inc. (TDI) has provided customers with an extensive range of rotor engineering services, including diagnosing and resolving various balancing issues. In an effort to meet growing consumer demand and reinforce our commitment to providing the most accurate rotor balancing services, we’ve expanded our balancing capabilities by acquiring a new HM 20 Schenck Horizontal Balancing Machine.

This state-of-the-art machine represents the latest in rotor balancing technology. One of the main benefits of the HM 20 is its hard-mounted bearing design, which ensures rapid changeovers between rotors. This feature allows us to handle significantly higher volumes of balancing jobs without compromising the quality and repeatability of the work, and increasing the efficiency of our operational capabilities.

Additionally, the HM 20’s modular design makes it easy to modify the setup for a wide range of components by using various purpose made attachments. These features increase the versatility of the balancing machine and allow us to meet the unique demands of customers regardless of industry or application.

Differentiating our services, our balancing operation offers:

- Accuracy & Precision: We address a wide selection of balance testing needs, including unbalance tolerances below ISO G2.5 specifications. We’ve developed distinct processes to ensure accuracy and repeatability of our balancing work, including studies and analytical method for asymmetric rotors.

- The Facility: Our balancing machines are carefully set up, calibrated and maintained by experts so that they are properly calibrated and dynamically isolated. We have also set up a dedicated area to efficiently perform the various tasks involved in balancing work. We offer comprehensive options for balance correction methods ranging from simple dremel to precision CNC machining.

- Quality: We offer full inspection services ranging from CMM dimensional checks, visual checks and manual measurement by experts. We follow AS9100 Aerospace Standards. All of our work is recorded and fully traceable. We also comply to various requirements to serve ITAR works.

- Handling: We understand the importance of proper handling and protection of the critical features of customers’ parts. Our engineers will work with you to fully capture your handling requirements in the balancing operation. Our team can support your needs in design and provision of protective gears.

- Engineering Support: In addition to balance correction services, Test Devices (and our parent company, Schenck) offers advanced technical support in designing customized balance toolings, fixtures, as well as offering engineering consultation on planning balancing processes and designing balancing features for your rotors. Dealing with balancing as an “afterthought” often results in an expensive problem.

Balancing Services at TDI

At Test Devices Inc., we offer a broad range of timely and cost-effective balancing services for virtually any size of rotor. Our advanced equipment (including the newly acquired HM 20 Schenck Horizontal Balancing Machine) will balance the most intricate and complex parts in the aerospace industry.

Our services also include the design and manufacture of customized balance tooling to help produce unique and precisely balanced components.

Our staff consists of highly qualified and experienced industry experts, engineers, technicians, and consultants who provide rotor balancing solutions in hundreds of challenging applications for world-renowned clients. We partner with Schenck, the experts in balancing, to combine their advanced technology and knowledge base with in-depth expertise and software support. We also work closely with our customers, analyzing each specific case to determine the best balancing methods and strategies.

- Selection of a machine with the proper sensitivity for the component and balance requirement

- Creation of robust controlled processes for production work to ensure repeatability from lot to lot

- Accuracy improved by ensuring consistency of the setup (ie. Little details) and rotor specific calibration

- Repeatability by using “master” rotors to ensure part specific configuration/calibration is correct and consistent

- In-house true engineering capability to design of component-specific balance tooling that considers dimensions, tolerances and centerline error

- Drawing upon our Schenck expert balancing colleagues to address unusually complex balancing requirements

- Selection of appropriate material removal methods (milling/grinding) to address customer requirements

- Utilizing trained balance personnel

The Balancing Experts

Proper balancing of rotors and other rotating components is essential to ensuring the efficiency, longevity, and safety of your machinery and equipment. Furthermore, a good balancing reduces your equipment’s maintenance requirements, eliminating the down time and costs associated with frequent repairs and part replacement.

Although it’s relatively simple to diagnose an unbalanced part, careful selection of a balancing service provider is crucial to guarantee optimal results. At Test Devices Inc., our technical staff have seen it all and are willing to assist you with your balancing needs.

If you would like to learn more about the risks of improper balancing and how you can avoid them, download our comprehensive eBook, Balancing 101, or contact our team today.

Comments are closed