Top 3 Reasons to Choose Us for Precision Machining Services

Leave a CommentIn modern manufacturing operations that create critical rotating parts, each step, from forging to finish machining to final inspection, contributes to the overall quality of the finished pieces. To ensure the highest level of precision and reliability of your parts, it is essential that your semi-finish machining service provider has robust manufacturing processes in places relative to producing critical rotating parts. Look for full-service shops that offer high-quality, reliable, and consistent machining services.

One-Stop Shop Full Service Manufacturing

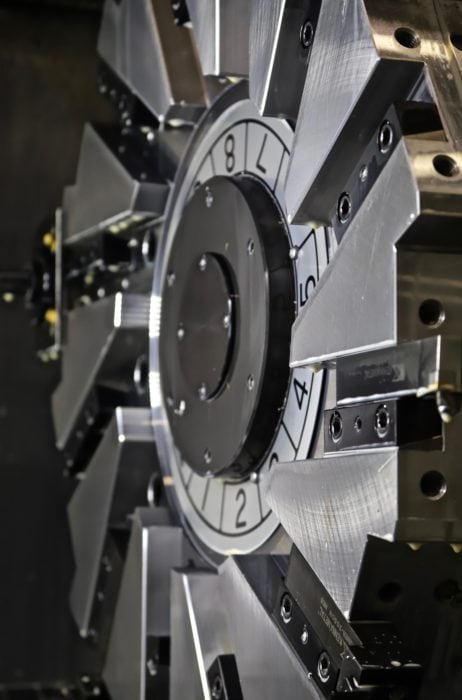

At Test Devices by SCHENCK, we have a highly skilled and experienced staff with the expertise in machining safety critical rotating parts from the most challenging aerospace alloys. We observe strict adherence to AS9100 and ISO9001 standards. Our talented team of engineers and machinists, combined with our suite of on-site resources, allows us to provide a full-service approach to manufacturing that is unique in our industry, combining machining, inspection, and spin testing operations under one roof.

High-Quality Expertise in Precision Machining

The customers we serve demand the highest levels of quality, accuracy, and compliance with industry standards. We are the premier provider of precision machining services for aerospace OEMs, operating in strict compliance with the AS9100/ISO9001 standards. Throughout our over 40 years of experience in working with critical aerospace rotating hardware for testing and production, the Test Devices team has continued to provide unparalleled precision and reliability in sonic, rough, semi-finish, and pre-weld machining services.

At Test Devices, our operation not only conforms to the AS9100/ISO9001 standards, but we comply with various QPRs for leading jet engine OEMs. Our quality assurance team is staffed with the most experienced professionals, including on-site quality process experts, designated quality representatives, and dimensional inspection and CMM experts. From forging state to completed semi-finish machined conditions, we are committed to providing the highest levels of quality, dependability, and precision by employing controlled manufacturing processes, including:

- Component specific CNC/CMM programs

- Detailed operation sheets

- Inspection plans

- In-process control

- Dedicated and accessible operations management

- Direct and frequent communication with customers

Customer Focus

Being flexible and responsive to the customers’ needs and constantly changes is a necessary capabilities in the today’s manufacturing world. Whether it is a change in requirements or specifications, schedules, test criteria, or delivery times, providing exceptional customer service requires a commitment to communication. Frequent personal contact with each customer ensures that we are aligned on expectations and are meeting their needs.

All our customers are confident in our ability to respond quickly to urgent changes that could impact the manufacturing or delivery schedule. Our production manager maintains close working relationships with our customers, as well as coordinates with all departments daily on customer requirements. From machining to inspection, spin testing, balancing to shipping, every department is in lock-step throughout each step of the project.

Choose Test Devices for Your Precision Machining Services

Though Test Devices specializes in rough and semi-finishing of rotating parts in aerospace, the same high standard in the quality of work, and operational excellence could serve many other industries and customers with similar needs. Through our reputation for quality and professionalism, as well as our four decades-long history of success, our customer base continues to expand across sectors such as automotive, energy storage and generation, electronics, and medical devices.

Our dedicated and seamless production management team combined with our highly skilled and experienced team allow us to provide machining, balancing, and spin testing operations under one roof. For more information on our precision CNC machining or alloy machining services, please contact us today. To learn more about our precision machining tools or processes, please download our eBook.