Crack Detection: Life Testing Without Inspections or Risks

October 1, 2013

This testing is a long process and typically includes multiple inspection interruptions. Test Devices’ Crack Detection system can reduce or eliminate the need for inspections that add cost and time to what is already a high-investment test. This unique capability is available for both simple LCF testing (ambient, normal speed profile) and advanced testing such as high temperature testing, thermal gradient, advanced instrumentation, complex speed profiles (mission profile), and testing in partial atmosphere conditions.

LCF testing is conducted by rapidly accelerating and decelerating a test component in a spin test machine (or spin rig) to simulate the duty cycles of the engine in operation and evaluate the fatigue performance of the part over the expected life. Test programs requiring 50,000 cycles, 100,000 cycles or more are typical for an aircraft certification effort, and can take months or even years to complete! The primary goal of such testing is to demonstrate the fatigue performance of a part. While verifying the cycles to failure is an important aspect of the testing, it is desirable to stop the test once a crack has been identified, but the part has not failed catastrophically (burst). This preserves the part for detailed material analysis and evaluation. The traditional approach to LCF testing requires frequent inspections as the test component accumulates cycles and approaches its expected life limit. For example, a part expected to last 75,000 cycles may have inspections every 10,000 cycles or at 50,000 accumulated cycles. After this, the inspections may be increased to a rate of every 2,000 to 5,000 cycles. This approach increases the possibility of finding a crack prior to a burst, but adds considerable time and expense to the test program. This frequent inspection method, however, does not prevent a burst event that is due to a quickly progressing crack.

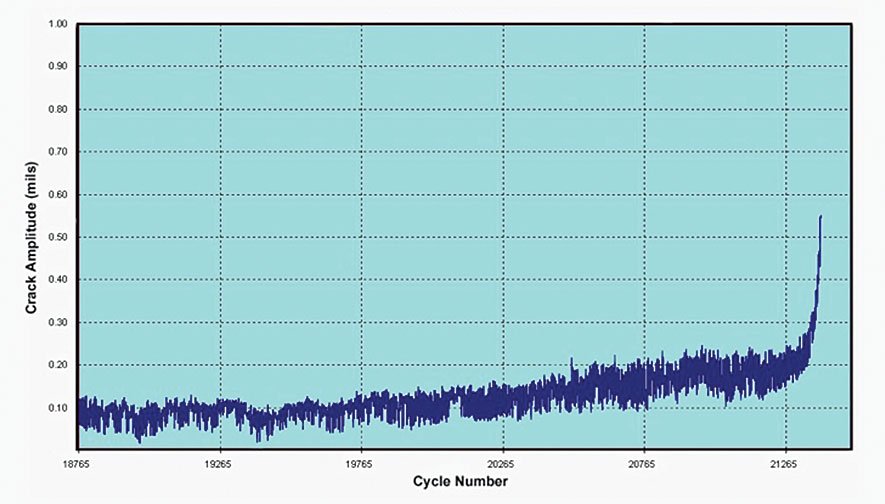

Test Devices’ patented Crack Detection system is a real-time, health-monitoring solution that reduces or eliminates inspection costs and delays. This results in shorter and less expensive LCF programs, and has the added advantage of enabling customers to conduct crack propagation studies. The system is also a valuable insurance policy in the event of a tooling failure. Crack Detection is available for all LCF testing performed at Test Devices’ test facility. The Crack Detection module uses a non-contact probe to constantly monitor and measure the status of a rotating component. Changes from the baseline, such as a crack formation or relative movement within the assembly, will cause a shift in unbalance of the rotating component. This behavior is closely monitored and analyzed to evaluate the distinct amplitude and phase change of the resulting vector. Changes in this condition usually indicates that a crack has developed or discloses some other important change such as a loose tie bolt, dummy blade walking out of the slot or loss of assembly fit due to fatigue distortion. Simple vibration monitoring systems cannot do this because cracks or other anomalies rarely cause observable change in vibration amplitude. The machine will automatically halt testing if the monitored condition reaches set condition, allowing high-confidence continuous testing (24/7 unattended).

Using a rotor health monitoring system, such as Test Devices’ Crack Detection module, offers the ability to halt a test before burst, allowing metallurgists to quickly find the crack initiation point, analyze disks without collateral damage and evaluate the crack propagation behavior. Without burst damage, the crack surface is perfectly preserved, which allows precise determination of crack type and growth rates.

This proprietary method has been in use for more than 15 years and has proven to be extremely reliable. Without this system, the only way to avoid burst and preserve the part is to frequently interrupt a test for interim inspections. Unfortunately, this can be a time-consuming and expensive approach – especially if the test requires major disassembly to gain access to blade roots or other critical features. Test Devices’ Crack Detection solution is an attractive way to reduce testing time and expense, while simultaneously insuring against losing critical test assets. More advanced LCF testing (heated or complex cycle) are typically more expensive to design, set up and run, so a tool to reduce premature burst or additional test durations are even more valuable.