Optical Strain Measurement Vs. Traditional Strain Gauging

In mechanical engineering, “strain” refers to the degree and the way a structure deforms under a load. An understanding of the strain behavior, combined with the knowledge of the failure mechanisms of structural materials, allows intricate yet robust designs of modern, high-performance aerospace machines, including rocket and jet engines.

High-speed rotors, such as jet engine parts, are subject to very high stress induced by centrifugal force. The need to lighten the parts to enhance the performance of the engine must be balanced with its durability and structural integrity. Engineers must, accurately and confidently, know the stress/strain state of the rotor to make the critical design decisions.

What Is Traditional Strain Measurement?

Further limitation of the strain gauges is that it is a point measurement and is blind to the behavior of the surrounding strain field behaviors. The readings from a gauge placed on a certain position of a test rotor must be interpreted accurately to perform a meaningful comparison against an FEA model.

Optical Strain Measurement Applications in the Aerospace Industry

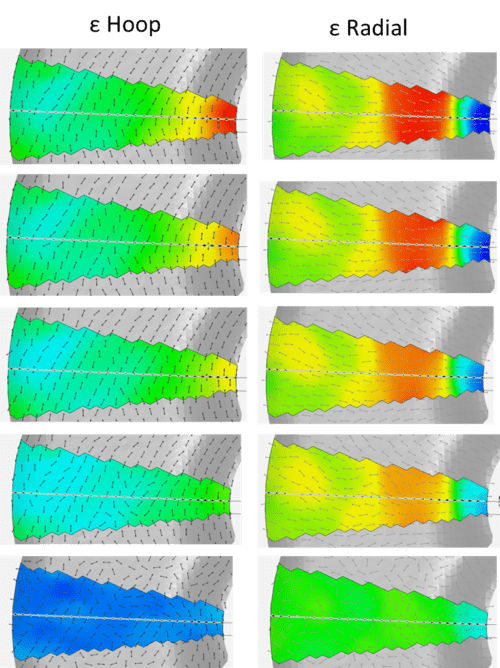

Test Devices Inc. has been interested in a non-destructive test and manufacturing process – the Rotating Optical Strain System (ROSS) – for some time. The ROSS is a non-contact strain measurement system which eliminates limitations, is less costly and provides more complete data, possibly allowing the measurement at higher temperatures needed for fully understanding the engine parts.

The ROSS will unlock a wealth of new information for material and component designers. The data is valuable for validating (or refining) the numerical models used in designing jet engine parts and gas turbine rotating parts as well as understanding the details of the failure mechanisms limiting the performance of existing parts.

Combined with advanced spin testing capabilities, Test Devices provides a unique testing resource for civil and military jet engine/propulsion system developers. The ROSS can accelerate the development of advanced materials and manufacturing capabilities across the gas turbine industry. It can provide the most relevant data to reduce risks in currently active turbine engine development programs.

Learn More

Optical strain instruments have been on the market for years, commonly used to measure strain in static objects. But in recent years, they’ve been steadily rising in popularity as more and more industry professionals begin to use them to measure strain in high-speed spin tests.

To learn more about how these optical strain gauges can benefit your testing and production processes, reach out to the team at Test Devices today.