Spin Testing for High-Speed Electric Motors

The growing prevalence of high-speed electric motors in aerospace, automotive and industrial equipment makes efficiently testing these devices more important than ever.

Many nascent high-performance motors are designed to operate at much faster speeds than traditional units, which means they require superior robustness and durability. Some of the biggest concerns regarding electric motor spin testing revolve around designing and validating the structural integrity, balancing strategy, and durability of the rotor. Successfully accounting for these traits help electric motors operate effectively in applications ranging from electric vehicles, drones, UAMs (Urban Air Mobility) and hybrid drive/propulsion systems.

Drawing from 40+ years of experience in advanced spin testing, Test Devices provides innovative solutions to challenging problems in engineering, testing, and manufacturing spin processes. We believe we can help accelerate your high-speed motor development by providing you with the most relevant test data.

Spin Testing Abilities

-

Rotor Growth &

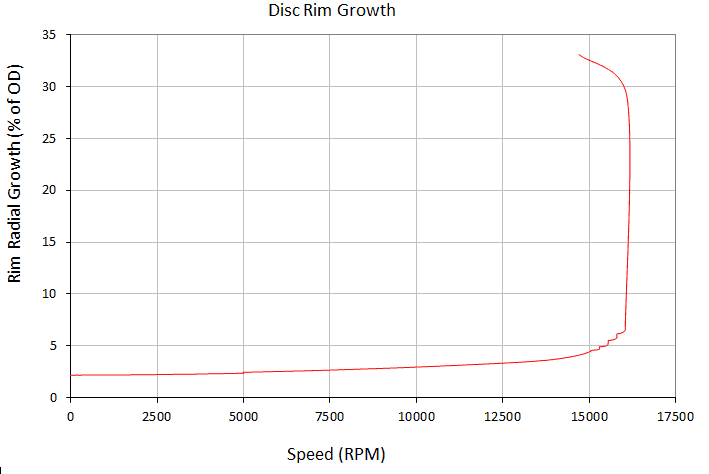

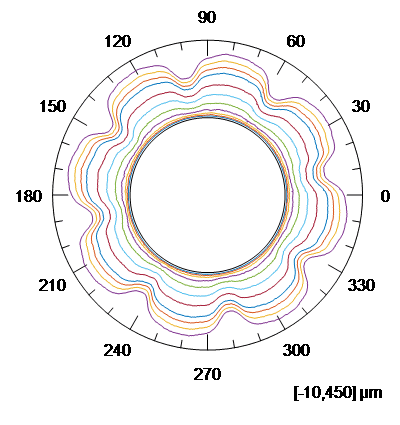

Profile MappingRotor Growth and Profile Mapping

TDI offers two types of rotor growth measurements: -

Burst Test & High-Speed

Video ImagingIn these tests, we take video recordings of machine equipment while we expose it to various types of stress. High-speed video data helps engineers understand the structural stability of the rotor and its failure mode.

-

Fatigue & LCF

TestingThese tests allow us to study the operational cycle fatigue (Low Cycle Fatigue, or LCF) and durability of the rotor. TDI’s proprietary Real-time Crack Detection System (RT-CDS) will detect the initiation of the fatigue crack to halt the test, helping to preserve the damaged rotor before it disintegrates. RT-CDS enables customers to know the exact location and properties of the fatigue initiation site, alleviating the need for time-consuming failure investigation work.

-

Heated Spin Testing

Thermal management is one of the most important concerns when designing high-speed motors. The motor’s operating temperature affects its material strength as well as the amount of air gap necessary for cooling airflow. This also helps accommodate rotor growth caused by thermal expansion.

Depending on the types of material used to construct rotors, their behavior could vary dramatically when operating in room-temperature versus high-temperature conditions.

-

Unbalance Budgeting

We offer expert design analysis services to estimate the range of unbalance in a given rotor design. We analyze a test piece’s geometric tolerances to monitor its influence on the rotor’s unbalance level, helping us estimate a value for this property.

By using a mathematical model to simulate the manufacturing process, we can compare up to 10,000 different combinations of the tolerance variations. The output from the analysis provides a probabilistic model of the unbalance in the rotor, which our clients can use to tune the design so that it minimizes scatter.

Balancing Services

Spin Testing and Balancing Services often go hand-in-hand.

Learn more about our balancing services here!