Custom Testing & Experiment Projects

Are you in need of help with developing a concept, designing, and performing an engineering or scientific experiment? With over five decades of experience in designing, analyzing, and performing complex advanced spin testing and building different kinds of unique industrial equipment, we have the expertise to offer you an innovative solution.

Modern spin testing is a complex engineering project that demands both analytical skills as well as hands-on pragmatism. It involves designing and operating arduous testing environments, cutting edge instrumentation, and control systems, and it requires that these are all carefully managed and orchestrated.

We take a collaborative approach with our customers to innovate and solve challenging problems. In many cases, due to the experimental nature of these projects, requirements and methods are often not fully defined, and it requires one to think strategically and take calculated risks. We employ a systematic approach to test hypotheses and develop a test solution that delivers a result.

Learn more about the custom testing & experiment services we offer.

Our Testing Expertise & Services

- End-to-End Service: Starting from a concept to performing a test and analyzing data, we can manage the whole aspect of your project.

- Designing & Building Test Systems: In a nutshell, this is what we do every day. We have a team of skilled engineers and technicians who design, develop, and build complex test rigs and machines to meet your needs.

- Test Automation: Automating testing and/or data measurement is a necessary and important facet of some engineering test projects. Examples include tests that demand a high level of repeatability or others that run for extended periods of time unsupervised.

- Instrumentation & Data Measurement: Selection and planning of sensors and measurement methods often goes hand-in-hand with designing an engineering test. A crucial consideration to avoid costly design changes in the later stage of the project.

- Data Analysis: Understanding and deriving insight from test data goes beyond just measuring data. It requires an intimate understanding of the experimental setup, measurement systems, and underlying physics of the experiment. Our Engineers are also skilled in the application of various DSP (digital signal processing) and signal processing techniques to analyze the data and differentiate the useful information from the noise.

- Numerical Modeling: Numerical Modeling often goes hand-in-hand with the test data to deepen the understanding of the experimental observation. We can help with construction and analysis of the numerical models, as well as the fusion of the test data to tune the model.

Custom Testing & Experiment Project Examples

We have designed and performed a wide range of engineering tests and experiment projects. Below are some samples of the work we done:

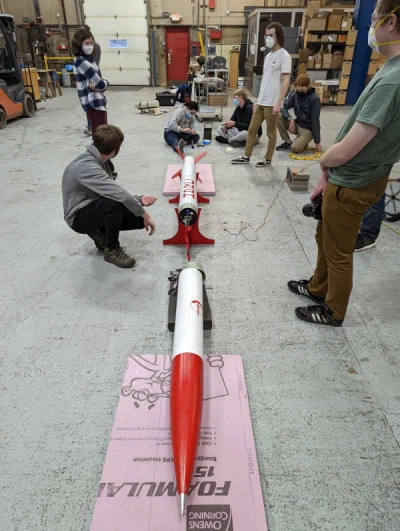

Rocket Stage Separation Test

We worked with the WPI HPRC (Worcester Polytechnic Institute High-Power Rocketry Club), a student sounding rocket team, to observe the behavior of the stage separation mechanism of their rocket with a High-Speed Video camera. The test captured the data to understand the interaction of the explosive charge and the structure of the rocket, and how it resulted in stage separation. This data was crucial for improving the rocket’s design.

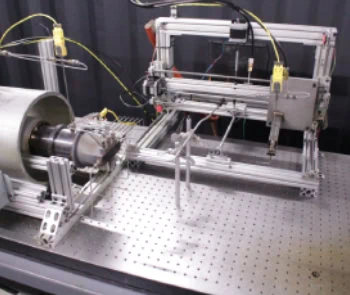

Coating Test with Air Cooled Blades

A US Air Force sponsored SBIR project. We were contracted to design and build a test rig with a test turbine blade-like specimen for evaluating the performance and the durability of the new thermo-barrier coating (TBC). We designed the test setup based on our TOAST rig at our subscale turbine testing facility.

The key components of this experiment included instrumenting a turbine blade-like test specimen and air-cooling the specimen. We designed and developed a robotic sample insertion mechanism, a cooling air supply and control system, test instrumentation, and data measurement setup for this project.

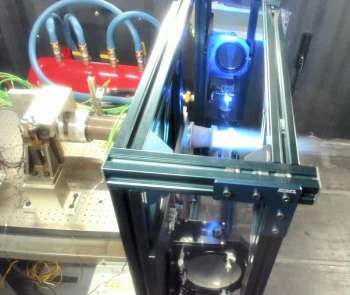

Development of Rotor Optical Strain System (ROSS)

As a part of the AFWERX sponsored SBIR project, we were asked to develop and mature the application of the DIC (digital image correlation) technique to observe the strain and displacement field in spin testing.

We designed and developed a precision synchronization system to orchestrate the angular position of the test rotor, a high power laser, and imaging systems to capture smearing-free images of high-speed rotating targets. We also developed an analytical process to process the images and compute the strain and displacement map on the rotor.

Highly Simulative Subscale Test

We designed and developed an advanced test system for a subscale disk specimen. The goal of the project was to demonstrate the steep thermal gradient capability over the rim and the bore of the small test disks.

The design of the test system incorporated an actively air-cooled disk bore, an induction heated disk rim, and a unique foil air bearing based rotor support system that allowed stable rotor dynamic behavior in a range of test atmospheric conditions (vacuum, partial atmospheric and atmospheric conditions). The experimental setup incorporated the use of a scanning pyrometer to observe the disk thermal gradient.

Industries We Serve

Test Devices by SCHENCK is a trusted testing partner for clients in the following industries:

- Aerospace

- Automotive

- Electric Motors (eMobility, eDrive, ePropulsion)

- Energy

- Commercial Space

- Defense

Contact Test Devices by SCHENCK for Custom Test and Experiment Projects

Test Devices by SCHENCK offers professional expertise in designing and managing customized engineering test projects to meet your needs and specifications. We understand the vital nature of engineering testing to ensure the performance of your products. For over 50 years, we’ve been a leader in engineering testing services—including spin tests—with an unparalleled reputation for safety and innovation.

We will guide you through the entire process, from design to execution, and offer hands-on support in analyzing your test data results. With our state-of-the-art facility, featuring an in-house machine shop and CMM inspection machines, you’ll obtain high-quality results quickly.

Test Devices by SCHENCK is ITAR-registered, with engineering processes that conform to AS9001 Aerospace standard. We are also ISO 9001:2015 certified, ensuring all of our testing services adhere to the highest possible quality standards. For more information on our spin testing capabilities, contact us or request a quote today.