Test Devices to Promote Non-rotational Testing Capabilities

June 1, 2015

When customers think of Test Devices, they probably think first of rotational (spin). In fact, rotational testing has always been the foundation of Test Devices’ service offerings. Today, we provide the most advanced spin testing capabilities available.

However, Test Devices has also long offered engineering expertise in assembling component systems for advanced spin rigs. The services are invaluable in the testing process and in developing and providing turnkey equipment for customers. Examples of component systems that must be assimilated are:

- Mechanical (motors, air turbines, hydraulic elevators)

- Electrical

- Hydraulic (elevators)

- Lubrication (high-speed bearings)

- Air flow (compressors, control valves)

- Electronic controls and data acquisition

- Instrumentation (sensors, gages)

- Heating/cooling systems (ovens, cooling jackets)

- Structural (spin rig and containment chambers)

Having observed increasing customer demand, Test Devices will now more actively promote systems engineering expertise. This will include developing and operating new non-rotational testing equipment and facilities to serve customers.

Examples of recent requests Test Devices has received for non-rotational testing services include:

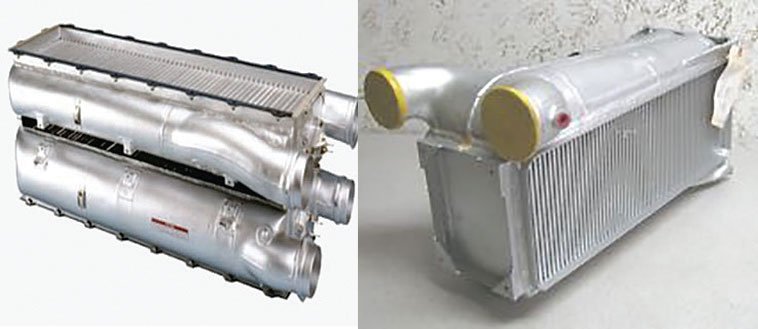

Aircraft air-to-air heat exchanger cycle testing: Intended to determine the number of ground-air-ground cycles that can be sustained without the development of leaks

Hot air drawn from an aircraft’s engines passes through one circuit of the system to warm cabin air flowing through the second circuit. Test Devices offers expertise in precisely controlling air stream flow rates and temperatures in a fast-acting, cyclic manner.

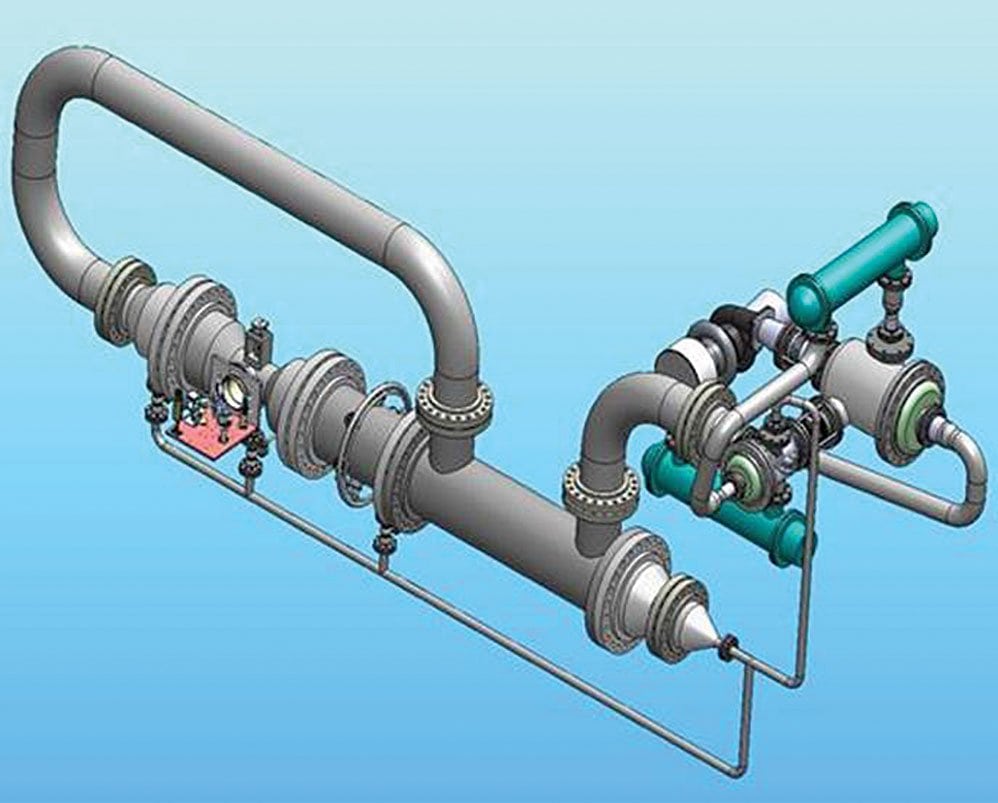

High-pressure cycling/conditioning: Intended to subject subsea equipment to realistic pressures in determining operating performance

Test Devices is expert in designing thick walled containment vessels and high-pressure fluid delivery systems.

Impact testing, e.g. aircraft turbine bird ingestion systems: High-velocity cannon used to propel foreign objects into a chamber containing the subject test article

Very high temperature, high-pressure combustion gas exposure rig: Simulates actual temperatures and pressures and environmental species in a high-pressure turbine section.

Combustion gas and cooling airflows are controlled on opposite sides of hollow specimens for through thickness temperature gradients. We can apply fast-acting temperature transients.

Contact us to learn more.

| Combustion gas temperature | 3500 °F |

| Cooling air temperature | 1200 °F |

| Combustion gas pressure | 20 – 30 atm |

| Transient gas temperature heating and cooling | 350°F/sec |

| Gas mass flow | 8 lbm/sec |

| Combustor exit gas velocity | 0.85 Mach |

Figure 4 – Specs for very high temperature, high-pressure combustion gas exposure rig shown in figure 3